Unibio, the leading sustainable protein company, has appointed Mr. Spencer White as Chief Financial Officer, effective 29th April 2024. Mr. White will join the…

15 Apr 2024The U-Loop® technology is a process occurring in nature and industrialized by Unibio. The process is described in this video.

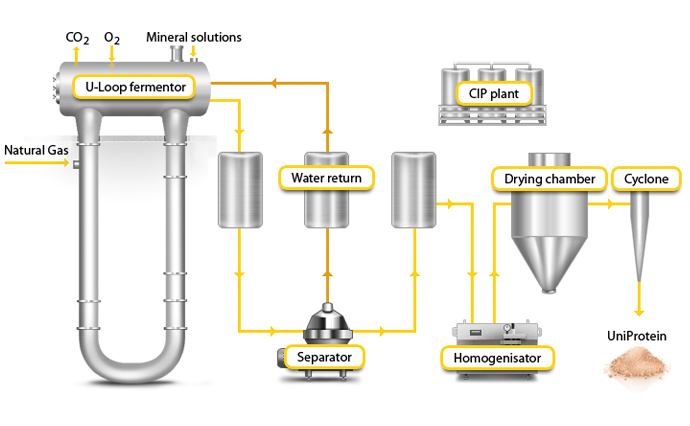

The concept underlying Unibio’s U-Loop® technology is simple: natural gas (methane) can be converted into a highly concentrated protein product which can be used in feed for animals (see diagram below).

The product has been branded Uniprotein® and can substitute other high quality protein products. On top of that, when the U-Loop® technology is employed in production plants, CO₂ emissions are reduced by 52% as compared to when natural gas is burnt for producing electricity.

The U-Loop® technology is patented under process patent No PA199900690. Unibio’s patent for U-shape and/or Nozzle-U-Loop fermentor and method of carrying out a fermentation process has been approved in Canada, Mexico and the US, and the patent for U-shape and/or Nozzle-U-Loop fermentor and method of fermentation has been approved in Mexico and is pending in Brazil, Canada, the EU and the US.

Natural gas is the main raw material used in Uniprotein® production, and it is used as the carbon and energy source. Oxygen is used for an oxygenation fermentation process, and ammonia is used as the nitrogen source. In addition to these substrates, the Uniprotein® culture requires water, phosphate and several minerals including magnesium, calcium, potassium, iron, copper, zinc, manganese, nickel, cobalt and molybdenum. Sodium hydroxide and sulphuric acid are used for pH regulation.

The fermentor and its design (see below) are the most important aspects of the U-Loop® production process. In traditional stirred fermentors there are problems with achieving sufficiently small bubbles (large surface area of the gas), and there is a large energy waste due to inefficient stirring of the bulk liquid. Furthermore, there are problems with cooling when upscaling.

Uniprotein® is produced in a continuous fermentation process. The U-Loop® fermentor with static mixers is used. The U-Loop® fermentor gives a high utilization of the gases, which are carried through the loop by the liquid flow in almost plug-flow mode. The gases are introduced at the start of the loop and stay in well-mixed contact with the liquid until they are separated in the headspace at the end of the loop.

Watch our video that explains how U-Loop® technology is used to produce Uniprotein®

Read our latest news articles to find out what's happening at Unibio

Unibio, the leading sustainable protein company, has appointed Mr. Spencer White as Chief Financial Officer, effective 29th April 2024. Mr. White will join the…

15 Apr 2024

Unibio, the leading sustainable protein company committed to feeding the world’s growing population, is pleased to announce that it has become a member of…

29 Nov 2023

Copenhagen, Denmark – Unibio, the leading sustainable protein company, will participate in COP28 United Nations Climate Change Conference 30 November to 12 December 2023…

13 Nov 2023